Noritake continues to be highly esteemed in providing complex designed abrasives for the Bearing industry.

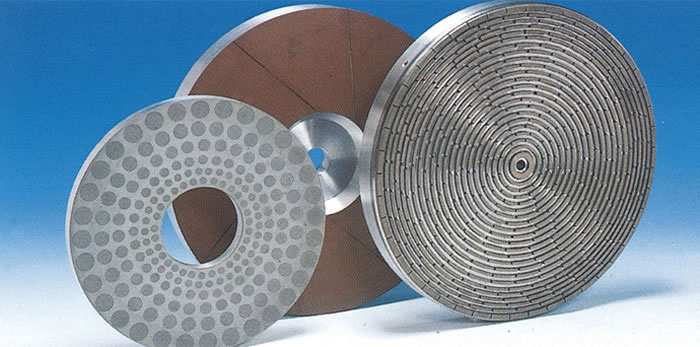

The Noritake Flatdy is a disc grinding wheel with a new bond system to produce a sharp cutting edge that delivers high quality, long life and high efficiency grinding. The Flatdy grinding wheel is great for grinding the bearing face. The Flatdy features stable cutting ability which is maintained by a continues honing of the cutting edge. The grinding load is absorbed by the newly developed high shock absorbing bond. Flatdy reduces work-piece defects by eliminating burning, breaking and deformation during production.

-

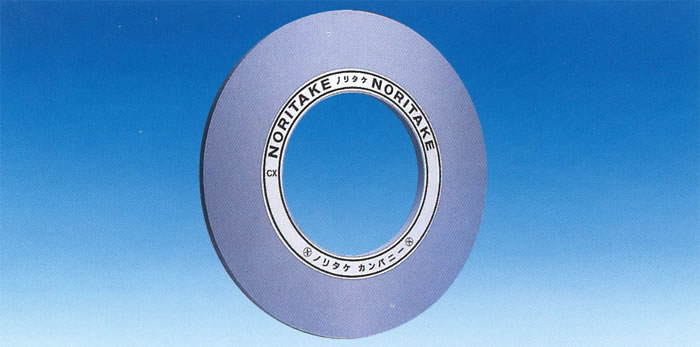

Ceramic CX

The CX wheel is ideal for grinding hard steels and gummy materials. The CX self sharping feature provides continues cutting...

-

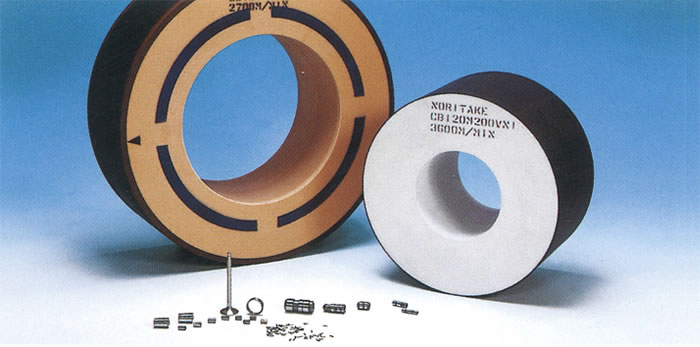

Centerless

The Noritake Centerless grinding wheels are used to manufacture a wide range of parts including Engine Valves, Injection Nozzles, Balance...

-

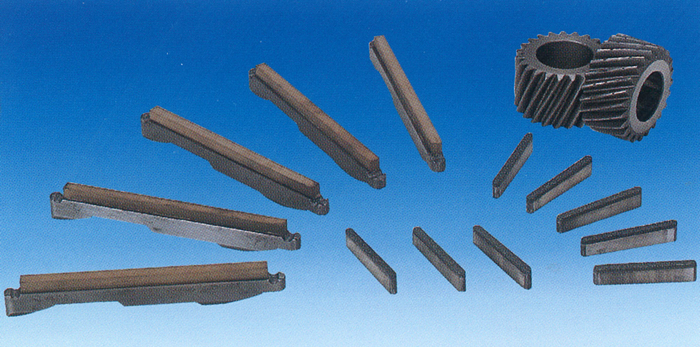

Diamond CBN Honing Stone

Noritake Diamond CBN Honing Stones are used for precision honing of the inner diameter of a cylinder. Diamond CBN Stones...

-

DDG Diamond / CBN

The DDG Diamond CBN wheel for double disc surface grinding uses diamond and CBN as abrasive grains. Resin metal and...

-

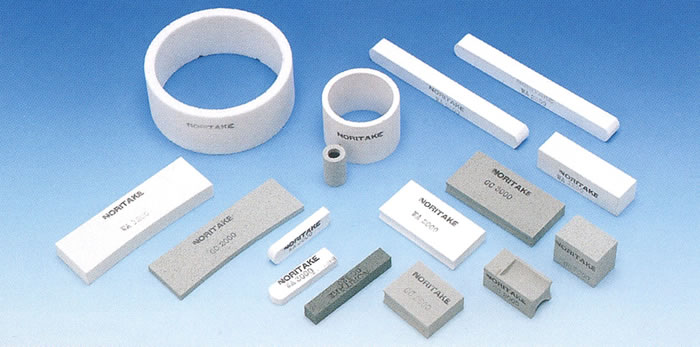

Honing Stone

Noritake provides many types of honing stone products but Keen Stone and Mr. Neo Lapper is our best. The Keen...