Noritake Diamond Dresser are created with synthetic diamonds to perform efficient grinding wheel dressing, truing and forming.

Synthetic Diamonds are produce by an artificial process, as opposed to natural diamonds, which are created by geological process. Synthetic Diamonds are designed with Noritake’s tolerances and parameters, which insures a consistent design. When using Natural Diamonds as a source for dressing there can be inconsistencies because the diamond shape and type are never the same. These inconsistencies within the diamond can cause improper dressing practices and bad wheel forming. Because of this Noritake uses Synthetic Diamonds over Natural Diamonds as a design bass for grinding wheel truing, forming and dressing solutions.

-

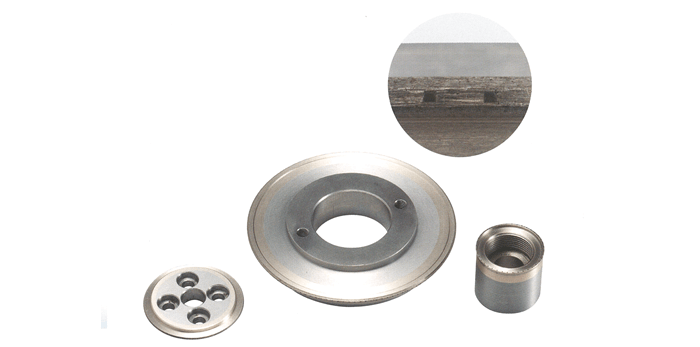

Grit and Impregnated

Grit and Impregnated dressers feature a synthetic diamond grain powdered design. The powder metal coating of the Grit / Impregnated...

-

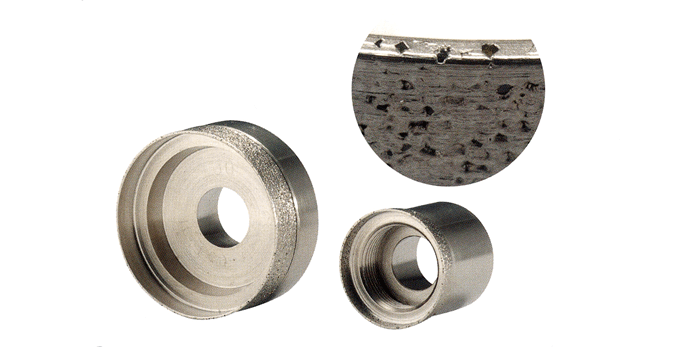

Electroformed Rotary

The Electroformed Rotary dressers are created by embedding synthetic diamonds with the use of electroforming. They feature a low dressing...

-

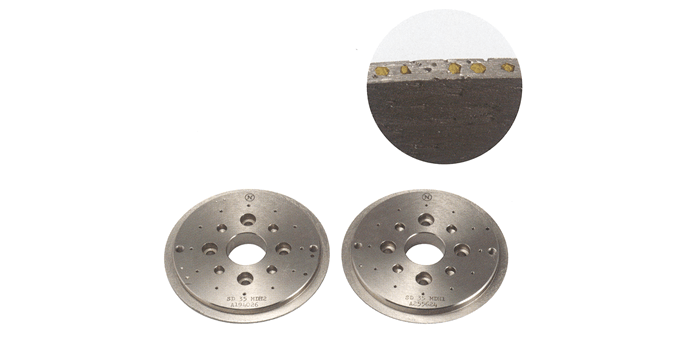

Metal-Bond Rotary & Scroll

Metal bonded rotary dressers feature a spiral shaped diamond design in a metal bond that can be consistently dressed particle...

-

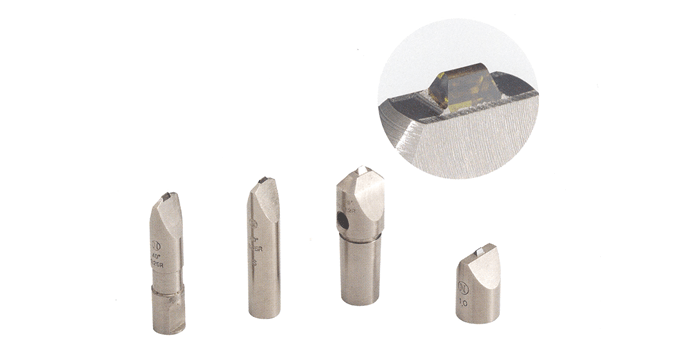

AD Forming

The AD Forming dresser features a monocrystalline diamond which is great for diamond wear resistance. The arrangement of the monocrystalline...

-

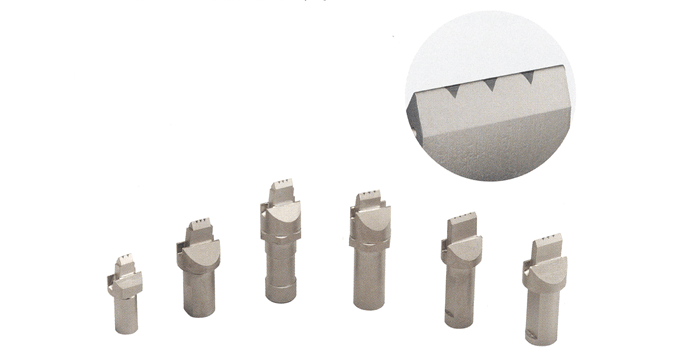

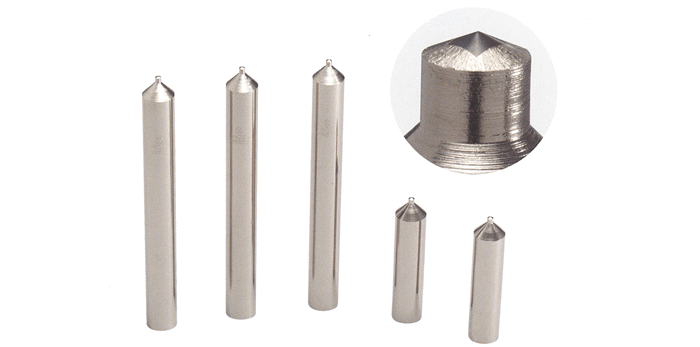

LL Single-Point

The LL Single-Point dresser features a synthetic diamond rod. LL Single-Point are used for general purpose grinding wheel dressing. LL...