Noritake grinding wheels play a significant role in Industrial applications.

From grinding engine components for land base turbines to silicon for Sapphire wafers. Noritake Industrial products have proven to withstand aggressive grinding applications while ensuring a premium work piece efficiency. You can always expect for Noritake grinding wheels to be consistent and cost effective. Our patented creative technology is what gives us the grinding edge to provide strategic products for countless applications for the Industrial market.

-

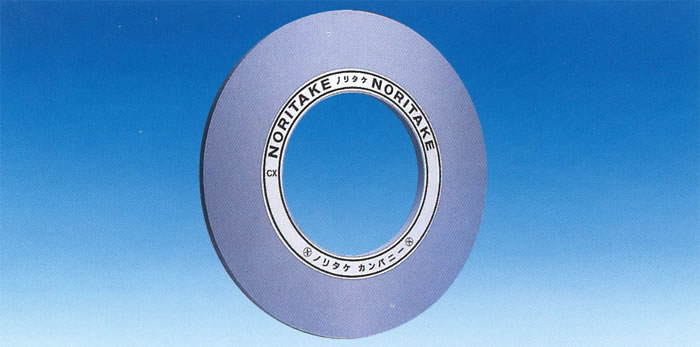

Ceramic CX

The CX wheel is ideal for grinding hard steels and gummy materials. The CX self sharping feature provides continues cutting...

-

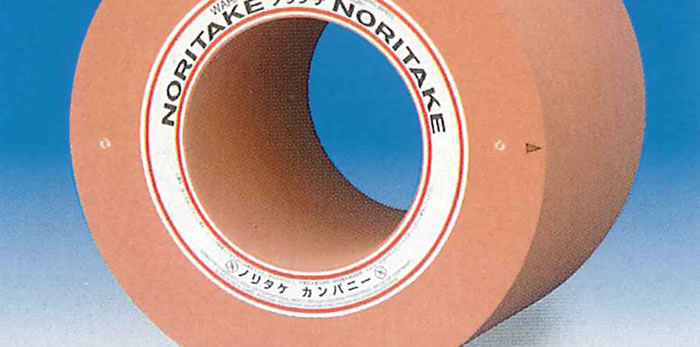

Large Porous Centerless

Noritake Large Porous wheel was designed for Centerless grinding that required a better cutting ability and increased grinding performance. The...

-

Free Cut Wheel

Noritake Fee Cut Wheels improve the cutting process by providing a cool cutting capability, long life and a precision cut....

-

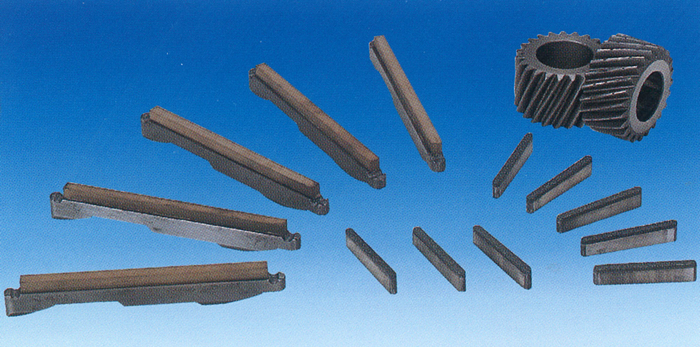

Diamond CBN Honing Stone

Noritake Diamond CBN Honing Stones are used for precision honing of the inner diameter of a cylinder. Diamond CBN Stones...

-

Diamond Cup Wheel

The Diamond Cup grinding wheel are designed for use with an electric tool for chamfering of concrete, stone materials, refractories...

-

Diamond CBN Roll

Noritake Diamond CBN Roll grinding wheel are created for the increasing demand for a grinding wheel with longer usable life...

-

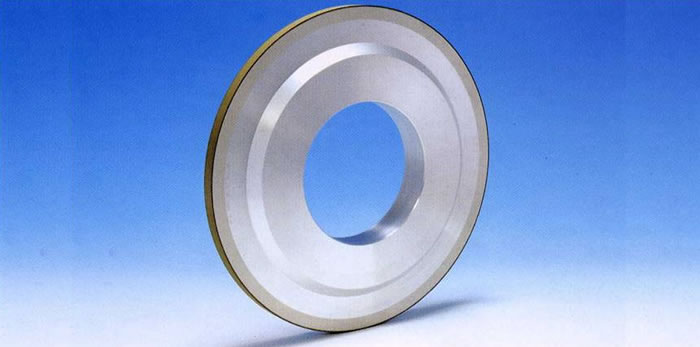

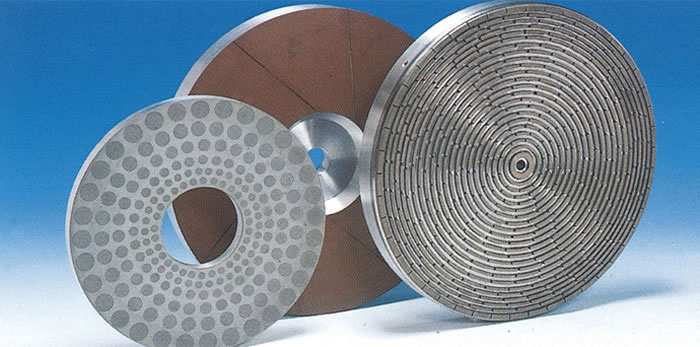

DDG Diamond / CBN

The DDG Diamond CBN wheel for double disc surface grinding uses diamond and CBN as abrasive grains. Resin metal and...

-

Vitrified V35

The V35 wheel retains outstanding cutting ability with low grinding force. It offers a long grinding interval and gives improved...

-

VRG / RUBBER GRINDING

The VRG wheel was designed for grinding rigid rubber and plastic materials. It is characterized by the countless pores covering...